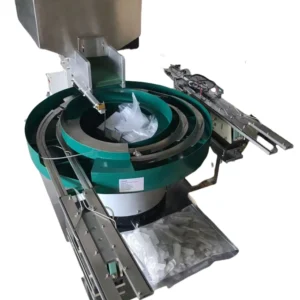

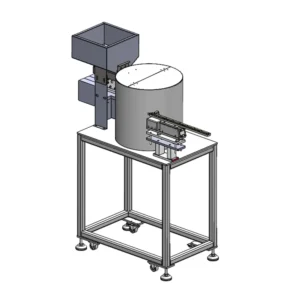

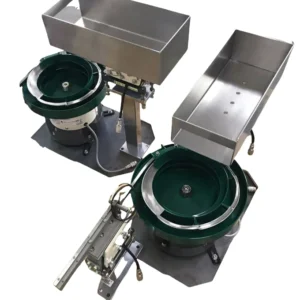

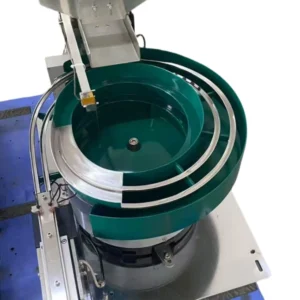

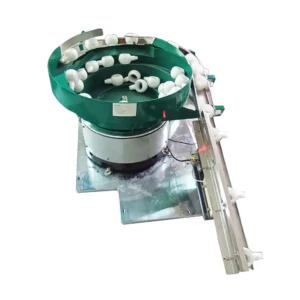

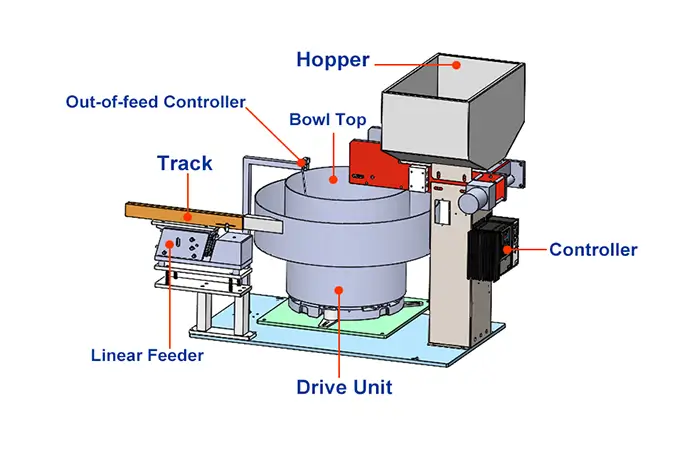

SWOER Hot-Sale Vibratory Bowl Feeders

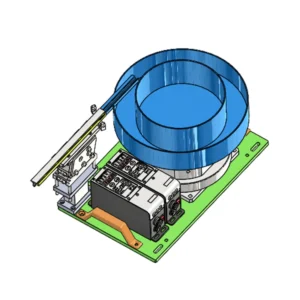

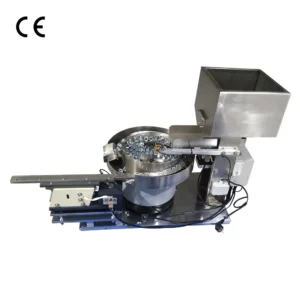

Types of Automated Feeder Systems We Made

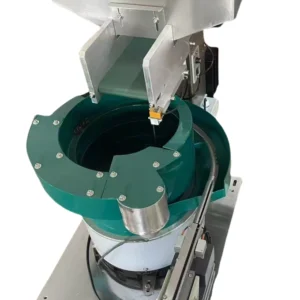

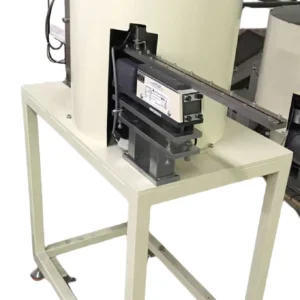

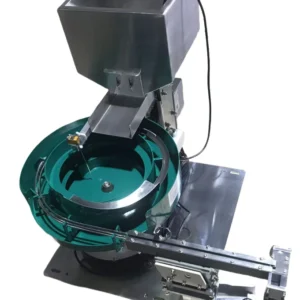

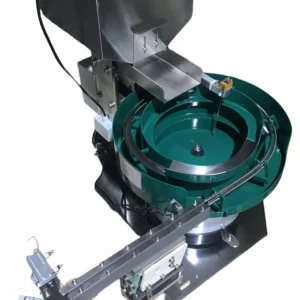

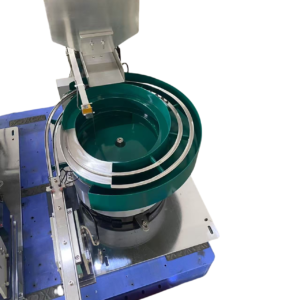

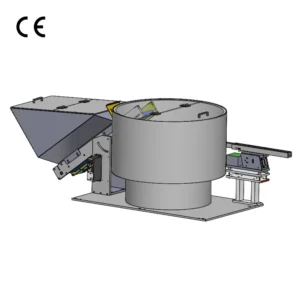

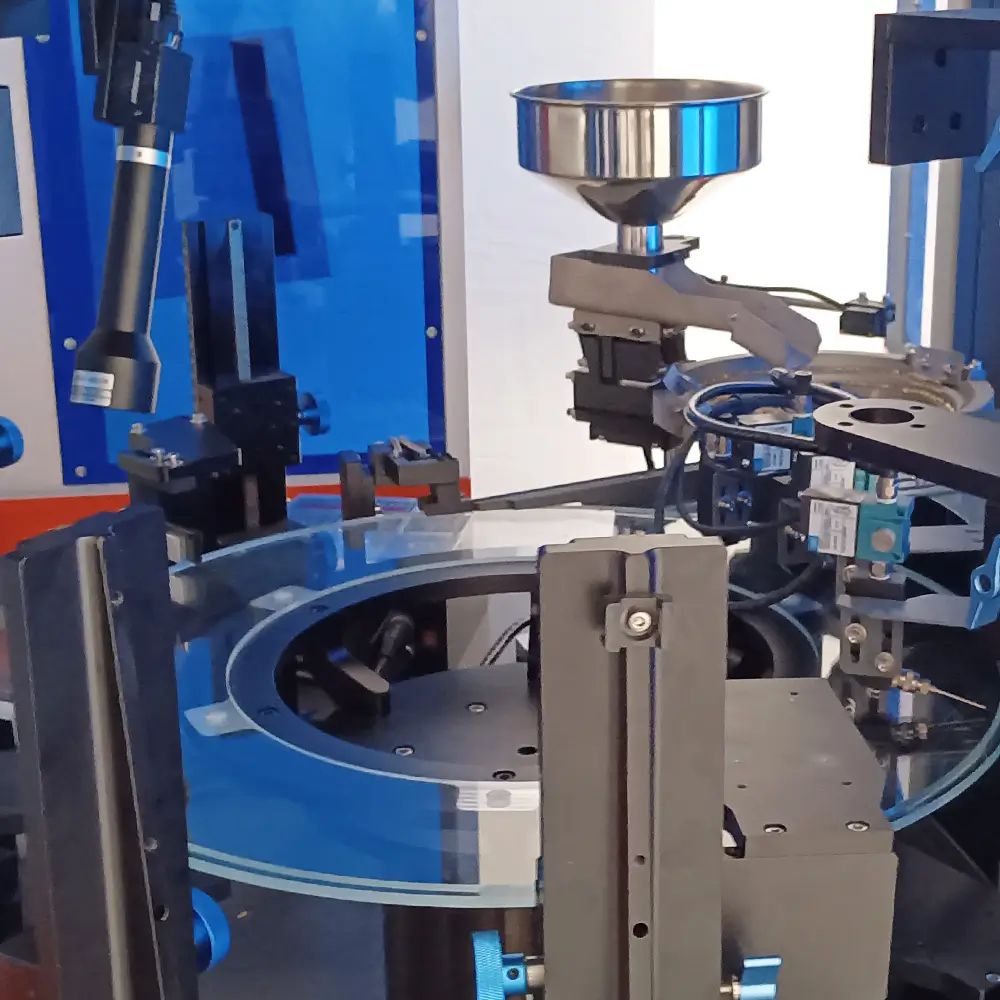

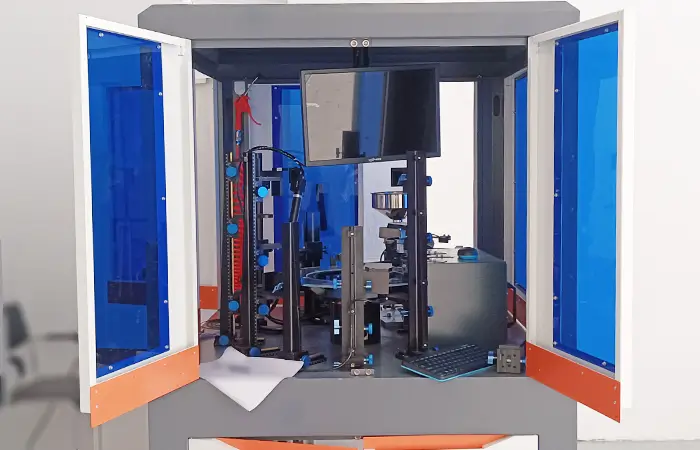

Rotary Visual Screening Machine

The Rotary Visual Screening Machine offers high-speed, accurate sorting with integrated visual inspection. It is ideal for detecting defects in parts and ensures precision and efficiency, enhancing your quality control process.

Get a free quoteGet Your Custom Bowl Feeder Machine

SWOWER is a trusted vibratory bowl feeder manufacturer with over 10 years of experience creating high-quality parts feeding solutions for various industries. It focuses on manufacturing high-quality customized screw bowl feeder systems, flex feeders, centrifugal bowl feeders, etc. to meet the various needs of customers. Here are your custom options:

These customization options empower our clients to tailor vibratory feeding systems precisely to their production needs, ensuring optimal performance and efficiency.

Get A free quoteVibratory Bowl Feeder Manufacturing Process

1)Designing: Engineers collaborate with clients to design feeder bowls and tracks using CAD software, ensuring precise alignment and efficient part movement.

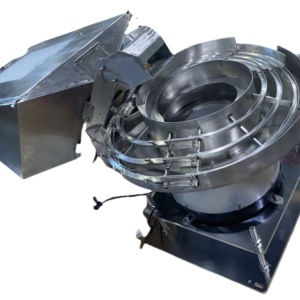

2)Material Selection: Quality materials like stainless steel are chosen for durability and cleanliness, while tracks are hardened steel for smooth part flow.

3)Fabrication: Bowls are fabricated using stamping, welding, or CNC machining, ensuring precision and smooth surfaces to prevent damage to parts.

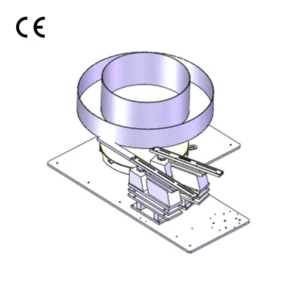

4)Coil Assembly: Electromagnetic coils are wound around bobbins to create electromagnets, generating the vibratory motion that drives part movement along the track.

5)Testing and Calibration: Rigorous testing and calibration ensure proper vibratory motion, track alignment, and feeding accuracy before packaging and shipping.

GET A FREE QUOTE

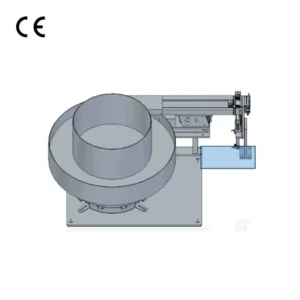

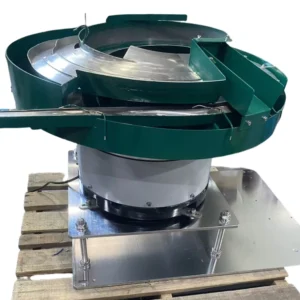

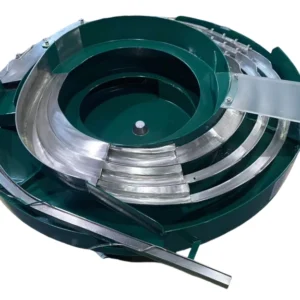

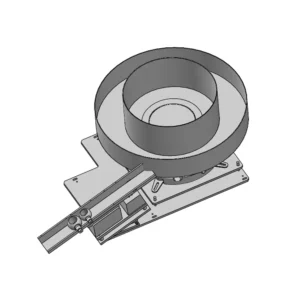

Vibratory Bowl Feeder Design Details

The Essence of Vibrating Bowl Feeder Design:

- Vibrating bowl feeders comprise intricate design components crucial for efficient part feeding. The bowl, carefully shaped and sized, optimally accommodates specific parts, while its tracks ensure seamless part flow.

- Precise tuning of vibratory motion is key. Engineers adjust frequency and amplitude for gentle handling and prevention of damage. Electromagnetic coils enhance tuning, accommodating diverse part sizes.

- Track design guides parts with minimized friction, enhancing adaptability across environments. Electronic controllers regulate vibration for consistent feeding rates, boosting industrial productivity.

- In conclusion, these design elements ensure reliability and efficiency in vibrating bowl feeders, indispensable in manufacturing.

Benefits of Vibratory Bowl Feeders

- Efficient Parts Orientation: Vibrating bowl feeders ensure consistent positioning, enhancing downstream processes’ efficiency.

- High Feed Rates: These feeders deliver parts reliably at a steady pace, boosting overall production efficiency.

- Customizable Design: Versatile design options accommodate diverse part geometries and sizes, making them adaptable to various applications.

- Reduced Manual Intervention: Automation minimizes labor costs and improves safety, while gentle handling maintains product quality.

Vibratory Bowl Feeders Application

Vibratory bowl feeders are versatile solutions that find application across a spectrum of industries, each benefiting from their precision, efficiency, and adaptability. Here’s a glimpse into how vibratory bowl feeders are revolutionizing different sectors:

Vibratory Bowl Feeders for Automotive Industry

Streamline assembly lines by precisely feeding small components like screws, nuts, and bolts. Ensure seamless integration of intricate parts in engines, transmissions, and electronic systems. Enhance productivity and reduce downtime by automating the feeding process for various automotive components.

Vibratory Bowl Feeders for Electronics Manufacturing

Facilitate the handling of delicate electronic components such as resistors, capacitors, and connectors. Improve efficiency in circuit board assembly by accurately orienting and feeding components onto PCBs. Minimize errors and defects by maintaining consistent part orientation and positioning during assembly processes.

Vibratory Bowl Feeders

in Pharmaceutical Industry

Enhance compliance with stringent quality standards by precisely handling pharmaceutical products, vials, and syringes. Optimize packaging lines by automating the feeding of pills, tablets, and capsules into blister packs or bottles.

Increase throughput and reduce manual handling of sensitive medical devices and equipment components.

Vibratory Bowl Feeders for Food Processing and Packaging

Ensure hygiene and sanitation compliance by using stainless steel vibratory bowl feeders for food handling applications. Improve efficiency in packaging lines by accurately feeding products such as confectionery items, nuts, and bolts. Enhance product presentation and reduce product damage during packaging with gentle handling mechanisms.

Why Choose Us as Vibratory Bowl Feeder Supplier

Professional Senior Designer

With more than ten years of experience in product manufacturing. Professional technicians provide you with professional advice. Advanced equipment creates high-quality products for you.

Competitive Factory Prices

One-stop service can reduce costs and improve quality standards. Arrange from design, material, processing, delivery time, quality inspection, and transportation. Reduce any additional costs throughout the process.

Fast and Convenient Delivery

Fast production, early delivery, reliable logistics, can provide door-to-door service. Various transportation modes meet different countries.

Best After-sales Service Provided

Improve product sales and technical after-sales service. 24-hour online video call, actively solving problems for customers.

What Our Other Customers Say About Us

After-Sales Support

1. Responsive Assistance

Need assistance or technical guidance after purchasing our vibratory bowl feeders? Our dedicated support team is just a phone call or email away. Count on us for prompt responses and personalized solutions to address your queries and concerns.

2. Technical Expertise

Facing a technical challenge or encountering an unexpected issue with your equipment? Rest assured, our team of experienced engineers and technicians is equipped with the knowledge and expertise to resolve any issues swiftly. We’ll work tirelessly to minimize downtime and keep your operations running smoothly.

3. Regular Maintenance

Preventative maintenance is key to prolonging the lifespan of your equipment and optimizing its performance. Our after-sales support includes scheduled maintenance programs to keep your vibratory bowl feeders in peak condition. Trust us to handle routine inspections, repairs, and component replacements, ensuring uninterrupted operation and minimizing costly breakdowns.

4. Continuous Improvement

We’re committed to continuously improving our products and services to better meet your evolving needs. Your feedback is invaluable to us, and we actively seek ways to enhance our offerings based on your input. Together, we’ll stay ahead of the curve and drive innovation in vibratory bowl feeder technology.

Our Partner

Are you looking to improve your production process?

We will work with you to understand your production process and discuss your options.

Vibration Bowl Feeders FAQs

Vibratory bowl feeders offer several benefits, including efficient parts orientation, high feed rates, customizable designs, reduced manual intervention, gentle handling of parts, and minimal maintenance requirements. These advantages contribute to increased productivity, improved efficiency, and enhanced product quality in your manufacturing operations.

Vibratory bowl feeders are versatile and can be tailored to accommodate a wide range of part geometries, sizes, and materials. Our experienced team can work with you to assess your application requirements and recommend the most suitable vibratory bowl feeder solution to meet your needs effectively.

We offer extensive customization options for vibratory bowl feeders, including adjustable feed rates, bowl sizes, track designs, and material options. Whether you need to handle delicate components or high-speed feeding, we can tailor the vibratory bowl feeder to match your unique specifications and production requirements.

Our team of experts provides comprehensive support to ensure smooth integration of the vibratory bowl feeder into your production line. We offer design consultations, on-site assessments, and installation assistance to ensure proper alignment and compatibility with your existing equipment and processes.

We pride ourselves on offering responsive technical support and comprehensive after-sales service to our customers. Our dedicated support team is available to address any questions or concerns you may have, and we offer training programs, maintenance services, and ongoing assistance to ensure the optimal performance and longevity of your vibratory bowl feeder.

We adhere to stringent quality control standards throughout the manufacturing process to ensure the quality and reliability of our vibratory bowl feeders. Our products undergo rigorous testing and inspection procedures before they are shipped to customers, and we stand behind the quality of our equipment with warranties and guarantees for added peace of mind.